COVID-19 update from WorkSafeBC

Expedited workplace closures – what employers can expect On April 11, 2021, an order of the provincial health officer (PHO) delegated specific powers to WorkSafeBC prevention

Expedited workplace closures – what employers can expect On April 11, 2021, an order of the provincial health officer (PHO) delegated specific powers to WorkSafeBC prevention

Today, the Provincial Health Officer announced new orders delegating specific powers of the Public Health Act to WorkSafeBC prevention officers. Under the new order, WorkSafeBC

Minister Ravi Kahlon has announced the new Circuit Breaker Business Relief Grant which will provide $50 million to help the 14,000 restaurants, bars, breweries, wineries,

Since mid-March, more than 20,000 essential workers at Alliance member companies have received their first immunizations. That initial priority campaign ended in late March. The health regions are waiting for direction from the province to determine whether, when, and how they may be able to resume priority immunization of production workers. We will continue to update you here as we learn more.

“This is not a joke.” Wayne Arondus, Chief Operating Officer at the Manufacturing Safety Alliance of BC, started calling members about an opportunity to immunize

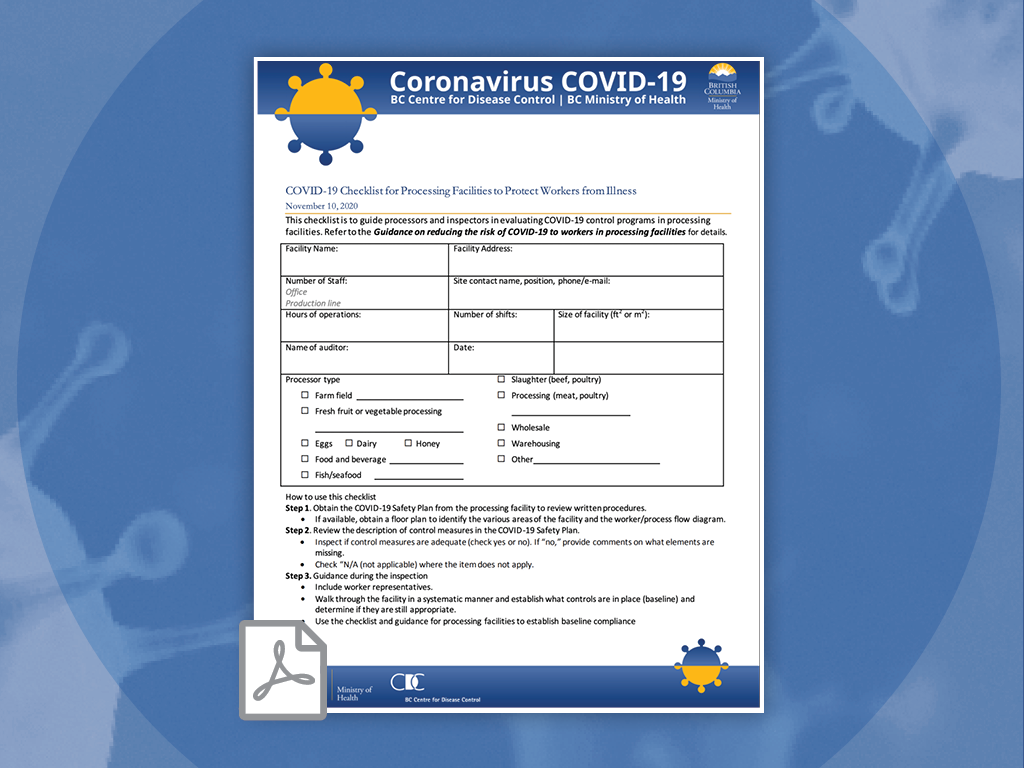

Effective November 7, the Provincial Health Officer issued new restrictions for the Lower Mainland and Fraser Valley. WorkSafeBC followed November 10, sharing plans to ramp up

Start from the top to implement the most effective controls possible in your facility. Postpone, reorganize, or plan work to eliminate the risk to workers.

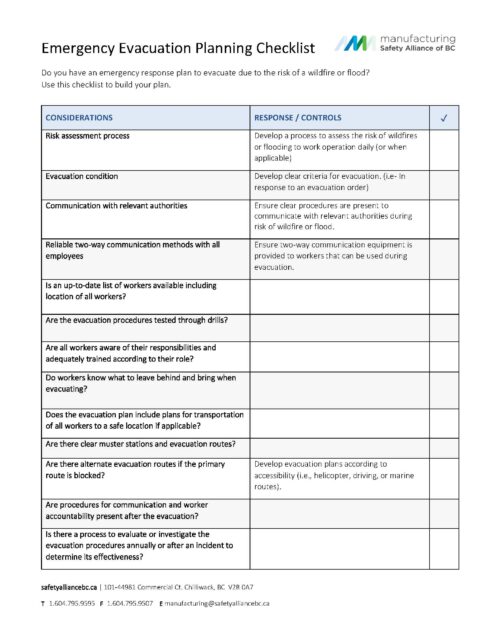

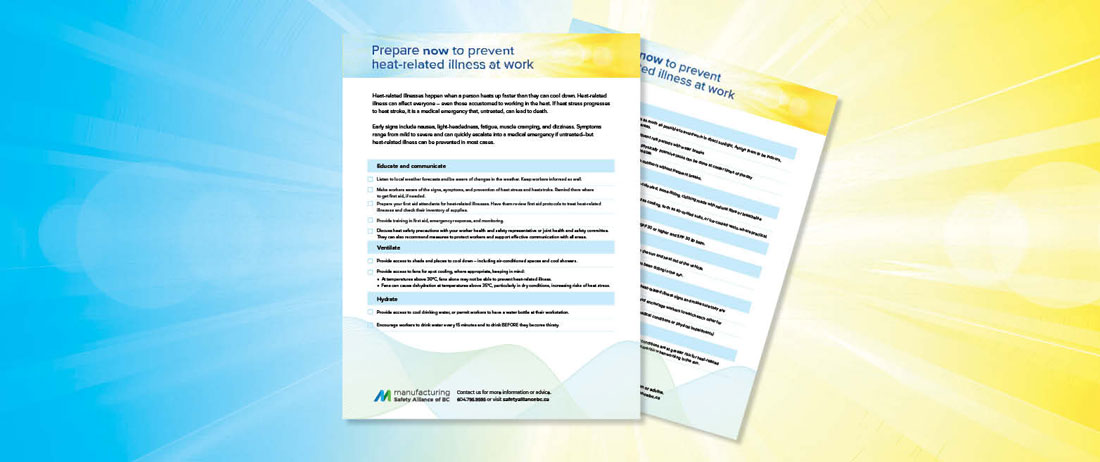

As you have been adapting to new methods and approaches for your business, our focus at the Alliance has been to research, develop, and share

As companies adjust their business to address the challenges of the global pandemic, many have expanded their online operations and moved to virtual workspaces for